Major Service

Other Special Service

What are you looking for?

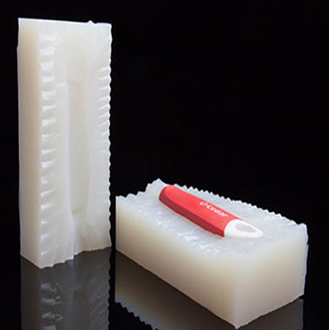

Vacuum casting is also called urethane casting. It is a copy technique formed by silicone mold to produce a small batch of functional parts. It is a great way to get parts with good surface detail and fidelity to the original pattern. Vacuum Casting is well known for its speedy and stable production way for prototyping manufacturing.

At Xin Pin, we will offer you a complete solution for accelerating your project development based on your CAD design. We can create parts for engineering functional sample parts, qualified display models, and more.

| Standard Lead Time | Up to 15 copies within 10 working days. |

| Standard Accuracy | Standard tolerance on±0.15mm/100mm. |

| Minimum Wall Thickness | To ensure that the mold is filled properly, minimum at least 0.75mm. But we recommend a wall thickness of at least 1.5mm. |

| Maximum Part Dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters). |

| Typical Quantities | Up to 25 copies per mold (depending on the mold's complexity and the casting materials). |

| Surface Structure | High-quality surface finishes comparable to injection moldings, such as Electroplating, Spraying, etc. |

The materials used in vacuum casting must accurately simulate a similarly vast range of industrial materials including ABS, polycarbonate, polypropylene, glass-filled nylon, and elastomer rubber.

Rubber is known as the most flexible and versatile material in the casting process, which is widely made gaskets and seals due to their enhanced durability and longevity.

It can withstand both extremely high and low temperatures. With its transparency outlook, it become very popular and attractive to meet a lot of requirements.

Polypropylene is one of the most favorite materials used in vacuum casting. It's cheap and easily available.

Retardance & fire resistance of filled ABS, like Hei- Cast 8150, PX858.

In addition, you may prefer to utilize the knowledge and experience to advise which materials are most suitable to achieve the properties you need.

Xin Pin uses advanced technologies to achieve quality and precision in our parts. There is a 4-step process summarized below:

1. Making the Master Pattern

We will produce a master pattern by CNC machine or 3D printing according to your CAD design.

2. Create Silicon Mold

The mold is made from immersing liquid silicone to form the mold. After the mold cures and solidifies, it will be cut into halves and removed from the master pattern. Then leaving a hollow cavity to process more parts.

3. Manufacturing Parts

Polyurethane is poured into the mold and cast under a vacuum environment.

4. Final Finishes

It will behave the post-treatment to the parts as our customer required, it can be cleaned, painted, polished, and coated.

1. Low Pricing

The material of the mold is inexpensive silicon compared with other steel molds.

2. Fast Turnaround

Every RFQ will be replied to within 12hours. The mold can be formed as fast as 48 hours. Normally takes 7-14days can be delivered to our customer.

3. High Quality

It is highly accurate with excellent surface texture. Our Professional technician will control every step process during manufacturing with a low rejection rate.

4. 20+Mold Life

It is suitable for small-batch production.

5. Material Options

We provide a wide variety of materials to meets the needs of almost all applications like ABS, Nylon, PC, TPE, and Acrylic-like materials. And it can be transparent, coated, colored, painted, and elastomeric.

Vacuum casting is a casting process for elastomers using a vacuum to draw the liquid material into the mold.

The range of applications for vacuum casting parts is massive. It is used for rapid prototyping and production in different kinds of fields.

Vacuum casting is a flexible and effective method for making high-quality rapid prototypes and end-use parts in low volumes and is considerably faster than other manufacturing processes.

In order to provide an accurate and timely quote, we only accept 3D CAD files in STP, STEP, PRT, or IGS format. For 2D drawings with reference, dimensions must be in PDF format.

For the 3D drawing, we prefer to STEP, IGS, or X_T format.

The maximum supported file size is 20MB, For larger or multiple files

Please place it into one folder and compress it into a ZIP and sent it to info@xpmodel.com.