Major Service

Other Special Service

What are you looking for?

Xin Pin provides metal CNC machining service for your custom part. Our capability enables us to fulfill your parts very quickly, even within 1 day.

Our facilities are equipped with the most cutting edge, high precision 3-, 4-and 5-axis imported machines, this is the best choice for your parts from prototype to batch production. In addition, we recommend CNC metal machining for functional, mechanical, thermal, or aesthetic validations.

| Metal CNC Machining Capability The metal CNC machining process involves a series of processes to achieve the specifications. Different materials will have different parameters. | |||||

| Material | Steel (All Grades) | Stainless Steel (All Grades) | Aluminium (All Grades) | Copper (All Grades) | Others (Tianium etc.) |

| Standard Dimendion (Block) | 1,016x508x636 | 1,016x508x636 | 1,016x508x636 | 1,016x508x636 | 1,016x508x636 |

| Standard Dimendion (Bar) | φ500x210 | φ500x210 | φ500x210 | φ500x210 | φ500x210 |

| Surface Rougness | Ra 0.8-1.6 | Ra 0.8-1.6 | Ra 0.8-1.6 | Ra 0.8-1.6 | Ra 0.8-1.6 |

| Tolerance | +/-0.002mm | +/-0.002mm | +/-0.002mm | +/-0.002mm | +/-0.002mm |

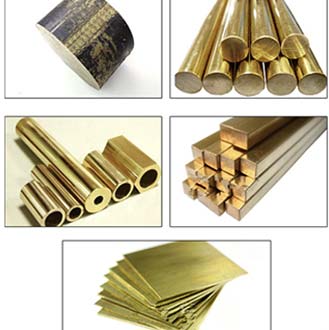

A good product cannot leave from the selection of materials.

At Xin Pin, we have wide choice for metal CNC machining available in stock.

Brass is popular for its medium hardness and high tensile strength. It is a metal alloy which made of a combination of copper and zinc. Hence, brass has a high scrap return, which can reduce the cost of raw material.

As we all know, Aluminum is one of the most common-use and cost-effective metals for CNC machining. It has flexible machinability, workability and versatility which used in different kinds of industries. The industries include aerospace, automotive, healthcare, consumer goods, and more.

At Xin Pin, we offer a range of grades Aluminum alloys for CNC machining. Such as some popular Aluminum 6061-T6, Aluminum 7075-T6 and Aluminum 6082. also offers aluminum machining in grades 1060, 1100, 2024, 3004, 5083, 5754, 6082, 6063, 6083, 7050, 5A12 and 5A02.

opper is mostly applied for use for the parts that require good electrical and thermal conductivity.

Similar to brass, copper has a very high machinability rate.

Industries such as automotive, consumer electronics, and healthcare sectors find this CNC metal very useful. There is no doubt that its other properties include good corrosion resistance.

The Stainless Steel is widely use in the metal CNC machining, because its corrosion resistance, high strength, and other physical properties. You can be sure that it is ideal for your applications. It is suitable for using in the automotive, aerospace, food, marine, and healthcare industries with its variety of grades.

This is the very high cost material which is impact on the total cost for the machining parts cost. It is mostly use in the medical and aerospace industries.

Titanium is an excellent corrosion, chemical, and temperature resistance material. Here is some common Titanium we used. These are Grade 2 Titanium and Grade 5 Titanium (Ti6Al4V). Grade 2 has a high corrosion resistance, while Grade 5 Titanium is the strongest Titanium alloy.

01. Analyze the processing drawings.

Our engineer will be checked the structure, shape, dimensional accuracy, material, roughness, and so on the details of the parts according to the drawing from our customer.

02. Determine the processing process.

And then, we will confirm the tooling, processing method, fix the JIG, processing sequence of each surface. We will take good command of the advantage of the machine to shorten the machining time to get good quality parts.

03. Reasonably calculate the coordinate value of the tool path.

Calculating the machining route with the Programming coordinate system gets the machining data.

04. Making the machining programming.

According to the parts of the tool path, tool trajectory data, and process parameters we've confirmed, programmers can be used in the parts machining.

The above 4 steps are CNC machining steps, which should be carried out when CNC machining, so as to guarantee the machining more efficiently.

Turning:

This is a form of CNC metal machining that makes use of lathes and cutting tools to remove the metal material from rotating parts.

Milling:

Milling engraves the material from a workpiece by the multi-point rotary tools. The features of milling processes include pockets, slots, flat surfaces, complex contours, and chamfers.

Drilling:

Drilling creates a round hole in the workpiece. A drill press or tapping machine is designed for drilling.

Reaming:

It is used to enlarge a previously drilled hole to a very precise diameter.

Boring:

Removing material to form a precise inner cavity within a workpiece.

CNC (Computerized Numerical Control) machining is subtractive manufacturing by using the cutting tool to engrave the block of the raw material.

Metal machining involves the use of a CNC industrial machine shop to process metals to meet desired specifications or requirements following the coded instructions on a computer. So, once metal machining has been programmed or coded, it won't need a manual operator to do its job of producing metal parts or metal products.

It depends on your parts structure, please feel free to send us to quote. We will send you the davorable price.

Yes, we offer CNC Turning (Lathe), as well as CNC Machining with 5-Axis, 3-Axis, and CNC routers.

Yes. Machined parts are generally used with concealed head 'PEM' brand self-clinching fasteners. Inserting these fasteners into blind holes has the extra benefit of a smooth finish on the opposite sides of sheet metal after the fastener is installed.

For the 3D drawing, we prefer to STEP, IGS, or X_T format.

The maximum supported file size is 20MB, For larger or multiple files

Please place it into one folder and compress it into a ZIP and sent it to info@xpmodel.com.