Major Service

Other Special Service

What are you looking for?

Choosing a reliable automotive supplier is vital in the development of the part. Rapid Prototyping services are the very commonly used and popular technology in the developing automotive industry. Xin Pin has worked with many automotive companies to provide various exterior and interior parts at all ranges of plastic, rubber, and metal material. We offer a variety of processes such as injection molding, CNC machining, Vauum casting, and Metal sheet, and so on to meet customers' specialized requirements.

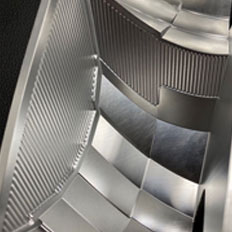

Xinpin in-house high-speed multi-axis CNC machines are fast, accurate and versatile, able to fabricates many different kinds of metals and plastic at any quantity to produce CNC auto parts CNC machines can also help us to make tools and dies for plastic injection molding and pressure die casting to support your higher volume production needs. We are pround of delivering durable, reliable, and highly-precised automotive part tothe global market.

Vacuum casting is one of the most cost-effective way to produce a volume of high-quality copies from a master pattern which is smiliar to injection molding. Our service is not only fast but we are experts at making vacuum cast parts with the fit and finish of a full production item.

3D printing is increasingly being used across all areas of automotive production. Aside from its extensive use for rapid prototyping, the technology is also being used to produce tooling and end parts. Our technology ability to produce functional parts for use in critical applications.

Xin Pin is one of the leading automotive injection molding companies. At Xin Pin, we offer best-in-class automotive injection molding services. As a full-service supplier, we have established long-standing relationships with the many auto company.

XIn Pin introduces lean production management and ERP to manage the orders, under the ISO9001 quality system, providing systematic guarantee for better fulfilling customer orders.

Aluminum extrusion is widely use in the Autoative industry. Our Xin Pin will conbime differenct kind of the processing for meeting your innovation requirements.

In addition, We are capable of offering CMM testing for your parts if required. And the different kinds of post-processing to the surface effect, such as the anodizing, polishing, blasiting, Powder Coating, Passivation, Painting, Heat Treatment and etc.