Major Service

Other Special Service

What are you looking for?

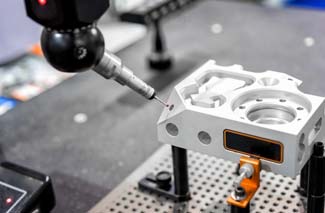

With the rapid development of technology, looking for a credible partner is good for your project verifying in time. At Xin Pin, we can offer high-quality prototyping, and low-volume manufacturing services like China laser sintering, China plastic CNC machining and China rapid injection molding to support your product development demands, including CNC machining, vacuum casting,3D printing, plastic injection molding, die casting and extrusion, and a series of finishing services.

Low volume manufacturing can be done by different machining methods. CNC machining, 3D printing, vacuum casting and rapid tooling. It is the best way to test the part before entering into the market.

| TYPE | DEFINITION | PRIMARY ATTRIBUTES | BEST RP PROCESS |

| Concept Prototype | It is used to show a particular product. It is good for the engineering team to hold a physical version of their design. | It didn't need 100% accuracy as the 3D design. If large numbers of prototypes are needed, then cost-effectiveness and speed are also should be considered. | SLA and SLS printing are ideal for concept prototyping as they are low-cost processes with fast production speed. |

| Assembly Prototype | The item is made from many different parts or need to assembly with another component. | The assembly prototype needs to be accurate in its geometries. It needs to follow geometries tolerances. | CNC machining, SLA printing, and rapid injection molding can be used to create assembly prototypes. In addition, as the material and the structure to do the consideration. |

| Testing Prototype | It is the functional prototype that is used to make sure parts can work under certain conditions. Most testing prototypes are made from metals, engineering-grade plastics, and other durable materials. | It needs to guarantee can be used with the assembly parts. | CNC machining and injection molding are mainly used for the testing parts. |

Manufacturing fast and quickly with below simple step.

Upload CAD File

2D&3D Drawing

Usually in STP, STEP, IGS, PDF, DWG Format

Getting Quote

Quotation will Be Replied within 2 Hours

Production

Once placed order, our engineer will analyze the drawing data, and go with the best.

Solution to Produce Part

Received Your Parts

Your parts will be delivered to your door directly.

For the 3D drawing, we prefer to STEP, IGS, or X_T format.

The maximum supported file size is 20MB, For larger or multiple files

Please place it into one folder and compress it into a ZIP and sent it to info@xpmodel.com.