Major Service

Other Special Service

What are you looking for?

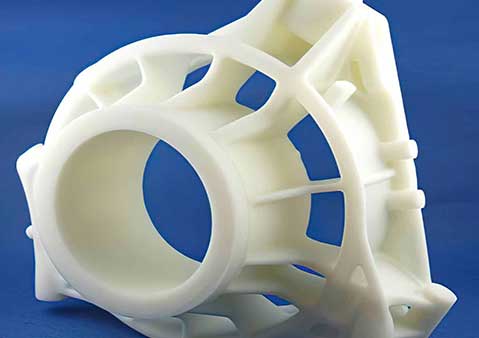

3D printing is the process of additive manufacturing instead of machining or subtracting material to form part. your digital designs into solid three-dimensional objects. It uses a computer-controlled laser to cure a liquid resin, layer by layer, to shape apart.

It is perfect for quickly verifying project design or function, or as an effective way to demonstrate your visual concept idea. At Xin Pin, it is our goal to provide the best prototyping solution that the parts can be satisfied with our customers.

3D printing services become popularity and usage in recent years because it’s simple technology with many applications. Here are some of the industrial applications of 3D printing services:

1. Healthcare

In the last several years there have been many 3D printing applications in the world of medicine.

3D printing is heavily used in the medical & dental industry, from bio-printing to prosthetics and medical devices. 3D printing applications in the medical sector are very versatile; for instance, CT scanning offers different patient-specific 3D printing parts China like dental appliances and implants, other benefits enhanced medical devices and personalized healthcare.

2. Aerospace & Defense

The Aerospace & defense industry has benefited from 3D printing since they manufacture functional parts used in aircraft, which include wall panels, air ducts, and structural metal components, etc. The primary advantage of using 3D printing in aerospace is weight reduction which significantly decreases payload, fuel consumption, and carbon dioxide emissions. Plus, it allows material efficiency, part consolidation, and low-volume production.

3. Automotive

Many automotive industries are using 3D printing in automotive industry. Automotive manufacturers print different parts using 3D printers. These include cradles, fixtures, and prototypes that are sturdy, stiff, and long-lasting. The key advantages are greater design flexibility, customization, and faster product development. Additionally, 3D printing helps create intricate geometrics such as internal channels, fine mesh, and thin walls.

4. Education

Every day, more schools are incorporating 3D printing methods into their curriculums. The benefits of 3D printing for education are that it helps better prepare students for their future by allowing students to create prototypes without the need for expensive tooling. Students learn about 3D printing applications by designing and producing models they can actually hold. Students learn about a variety of 3D printing applications by exploring design, engineering, and architectural principles. Such as the graphic design students can easily construct models with complex working parts. Students in the sciences can create and study cross-sections of organs in the human body as well as other biological specimens. Chemistry students can make 3D models of molecules and chemical compounds.

5. Construction

3D printing applications that are used in construction include extrusion (concrete/cement, wax, foam, and polymers), powder bonding (polymer bond, reactive bond, sintering), and additive welding. 3D printing in construction has a wide array of applications in the private, commercial, industrial, and public sectors. Advantages of these technologies include allowing more complexity and accuracy, faster construction, lower labor costs, greater functional integration, and less waste.

6.Art And Jewelry

An surprising application of 3D printing technology has been in the world of art and jewelry making. It facilitates the production of high-end products at a cheaper cost in a faster and efficient way. 3D printing services helps to minimize material wastage, risk reduction, and it’s highly sustainable. The additive manufacturing process enables manufacturers and engineers to design more complex designs, which is not the case with traditional manufacturing methods.

3D printing has evolved and has a wide range of applications. It is highly used in the medicine & dental, automotive, aerospace, education, and manufacturing industries are just a few of the countless ways, from education to medicine to industry to the arts, that 3D printing technologies impact our world today.

By simple edting CAD, engineers can conbime the design changes into their parts and re-print their parts. You can modify your design to manufacture at any time with wide selection material.

3D printing can manufacture prototypes and parts in as fast as 24 – 72 hours, because it don't need tooling or complicated fixture. It can reduces the time of R&D and production.

3D printing is part of the most cost-effective solutions for making one-off parts or small batches of production runs.

3D printing can produce rapid prototypes, functional prototypes, visual prototyping.

For the 3D drawing, we prefer to STEP, IGS, or X_T format.

The maximum supported file size is 20MB, For larger or multiple files

Please place it into one folder and compress it into a ZIP and sent it to info@xpmodel.com.